PENTENS PU-130 Polyurethane Spray Foam Insulation System

PENTENS PU-130 is a two component, 1:1 ratio, closed-cell polyurethane foam insulation system which when processed through suitable spray machinery (Grace etc.) will reduce a solid foam with exceptionally good compressive strength. The foam surrounds the structure in a lightweight blanket of insulation that creates a controlled comfort zone inside or outside the structure and contributes to its overall structural integrity.

ADVANTAGES

- Excellent on heat insulation

- Can be trimmed, sanded and, sawn, if necessary, painted and plastered

- Can be applied to damp surfaces

- Good adhesion to most construction surfaces, such as wood, brick, concrete, metals and many plastics

USES

PENTENS PU-130 is used for thermal and acoustic insulation in:

- Exterior or interior of agricultural buildings

- Ocean going yachts/canal barges

- Internal industrial roofing

- Domestic slate or tiled roofs

PENTENS PU-130 is also suitable used as a protective layer for waterproofing before backfilling soil at basement wall or pouring concrete at roof deck.

Standard PENTENS PU-130 should not be used on substrates below 0°C. When used externally, the foam must be protected from ultra-violet radiation and atmospheric degradation by a suitable elastomeric coating.

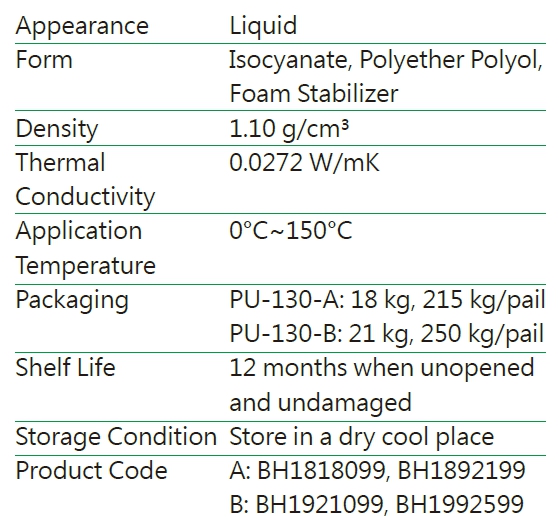

PHYSICAL DATA

APPLICATION

Equipment

PENTENS PU-130 can be processed through all standard foam spray machines. The machine should be capable of maintaining the mix ratio at ±2% accuracy and controlling the component temperatures at 40°C~50°C (variable).

Recommended machine settings

Block Temperature: 40°C~50°C

Hose Temperature: 40°C

Chemical Pressure: 1500 psi

Note

Chemical pressure of iso/resin not greater than 2000 psi difference.

Surface Preparation

The substrate should be clean, dry and free of dirt, grease, oil and loose particles. Climatic conditions must be suitable for spraying with regard to humidity and wind velocities.

Application

The foam should be built up in passes of not less than 15mm and not more than 30 minutes should elapse between pass.

SAFETY

Impervious gloves and barrier cream should be used when handling these products.

Eye protection should be worn. In case of contact with eyes, wash thoroughly with plenty of water and seek medical advice if symptoms persist.

If contact with skin occurs, it must be removed before curing takes place.

Wash off with an industrial skin clearer followed by plenty of soap and water. Do not use solvent.

Ensure adequate ventilation when using these products.