PENTENS T-009 Water-based Silylated PMMA Coating

PENTENS T-009 is a PMMA-silylated polymethylmethacrylate resin based coating of good hardness, adhesion, wear resistant, scratch resistant, UV resistant, anticorrosive

sealer, primer & finish for a wide variety of exterior and interior surfaces.

ADVANTAGES

- Outstanding adhesion

- High resistance to weathering and blistering

- Excellent color retention

- Zero VOC

- Additional features like termite-free, stain resistant and anti-sticking

- Easy clean-up

USES

Areas of use are such as:

- Bonding agent/Primer

- Clear/pigmented industrial floor coating

- Clear/pigmented sealer (mix with filler/aggregate)

- Clear/pigmented outdoor sports floor coating

- Clear/pigmented car park floor coating

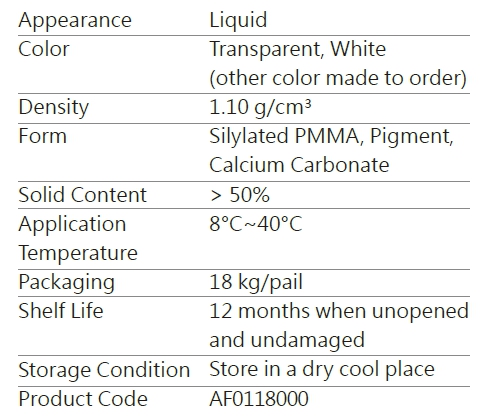

PHYSICAL DATA

APPLICATION

Surface Preparation

Surface must be clean, smooth, dry, and free of wax, grease, oil, loose or peeling paint, and other foreign material.

Bonding Agent/Primer

For better permeability and workability, PENTENS T-009 must be mixed with water on 1:3 ratio homogeneously prior to application, Applied by using roller/brush/squeeze/spray equipment.

Clear Coating

Use diluted PENTENS T-009 as a primer & sealer, followed by two coats finish. To dilute T-009 with pure water on 1:3 ratio homogeneously, and applied to the prepared surface by using brush or lamb wool roller or spray equipment.

Pigmented Coating

Use diluted clear PENTENS T-009 as a primer, mix clear T-009 with 5~10% compatible water-base pigment until homogenous and applied to the prepared surface by using brush or lamb wool roller or spray equipment.

The second coat may be applied as soon as the first coat has initially dried (typically 4 to 6 hours). The time will be dependent on the type of surface and the ambient conditions.

SAFETY

Impervious gloves and barrier cream should be used when handling these products.

Eye protection should be worn. In case of contact with eyes, wash thoroughly with plenty of water and seek medical advice if symptoms persist.

If contact with skin occurs, it must be removed before curing takes place.

Wash off with an industrial skin clearer followed by plenty of soap and water. Do not use solvent.

Ensure adequate ventilation when using these products.