PENTENS E-601 Solvent Free, Self-leveling Epoxy Top Coat

PENTENS E-601 is a two-component High Build Self Leveling Epoxy Systems with glossy, easy-to-maintain, chemical resistance finished surface.

ADVANTAGES

- Solvent free

- Excellent impact resistant

- Excellent chemicals resistant

- Good adhesive strength

- Low viscosity

- Easy to apply

- High mechanical

- Environmental friendly

USES

- Food Industrials

- Clean room

- High mechanical wear

- Traffic Zones

- Storage and logistic areas

- Chemical and pharmaceutical industries

- Institutional areas

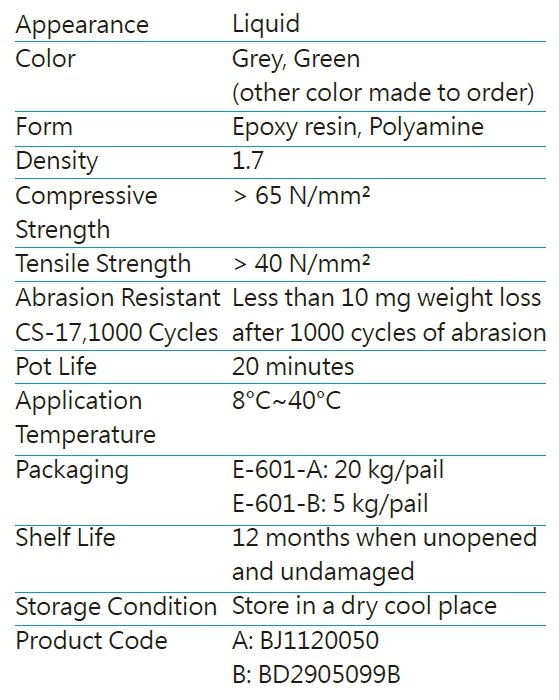

PHYSICAL DATA

APPLICATION

Surface Preparation

All the surfaces must be clean, free from grease, oil, laitance, and remove all the dirt and contaminants, which might affect adhesion.

Priming

Epoxy Primer E-10/E-501 to be diluted and mixed until a homogeneous substance. Apply with brush and roller. Allow primer to dry 12 hours or until tack free.

Epoxy sealer/screed

Distributes the mixture of PENTENS E-501 with graded aggregate over the floor onto the cured primer as a layer of sealer or leveling mortar screed, trowel the sealer/mortar screed to the required thickness.

Self-leveling Top Coat

A and B Component of PENTENS E-601 to be mixed until a homogeneous substance has been reached. Distributes the mixture over the floor.

Apply using trowel to achieve requiredthickness, and spike roller to release entrapped air.

Curing

Foot traffic after 72 hours, Full mechanical and chemical resistant is achieved after 7 days.

SAFETY

Impervious gloves and barrier cream should be used when handling these products.

Eye protection should be worn. In case of contact with eyes, wash thoroughly with plenty of water and seek medical advice if symptoms persist.

If contact with skin occurs, it must be removed before curing takes place.

Wash off with an industrial skin clearer followed by plenty of soap and water. Do not use solvent.

Ensure adequate ventilation when using these products.