PENTENS SPU-1000 Pure Polyurea Waterproofing Spray Coating

────── Taiwan Green Material Label Product

────── HKGBC Eco-Product

────── WRAS Approved Material

────── Passing NSF drinking water test

PENTENS SPU 1000 is a solvent free, two-component pure polyurea spray coating. The seamless coating provides an elastic yet tear resistant surface for applications subjected to extreme wear and tear, strong impact and chemical exposure. Except for some yellowing effect, the coating is suitable for outdoor applications.

ADVANTAGES

- High elasticity

- Extremely high mechanical properties.

- Seamless

- Good Chemical resistance

- Hard wearing

- Outstanding impact resistance

- Excellent bond strengths

- Fast Set. (30 Seconds)

USES

- Outdoor and indoor Floor slabs

- Potable water tank lining

- Sewage treatment plants

- Water theme park, Decoration Design, playgrounds

- Secondary Containment for chemical tanks

- Swimming pools and waste water tanks

- Pipe/pipeline coating & lining

- Flooring and Parking Decks

- Bridge Coating

- Truck Bed Liners- Line Striping

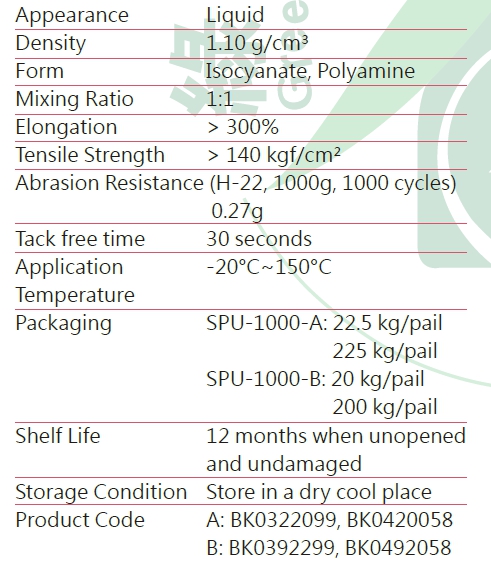

PHYSICAL DATA

APPLICATION

Surface Preparation

All the surfaces must be clean, free from grease, oil, laitance, and remove all the dirt and contaminants, which might affect adhesion. The

impurity outside the structure body should be cleaned thoroughly.

Any crack or water leakage area should be pre-treated and reinforced with PENTENS Repair System.

Application

This material is designed for application with heated, plural component airless spray equipment. Because of the relatively high viscosity and fast reactivity of this product,

pressure of at least 1800 psi-2500 psi (126-175 kg/cm²) are required to ensure satisfactory mixing.

Primed coats: PENTENS E-501S@0.5 kg/m²/coat

Finish coats: PENTENS SPU-1000 1.0 mm/1.10kg /m², 2.0 mm/2.20 kg/m², 3.0 mm/3.30 kg /m²

Curing

For optimum performance, PENTENS SPU-1000 should be allowed to cure for 12 hours before the finishing concrete, tiles etc.

Note

The best method to assure good penetration of the first coat into the surface is by application with a nap roller. The succeeding coats may be spray or roller applied.

SAFETY

Impervious gloves and barrier cream should be used when handling these products.

Eye protection should be worn. In case of contact with eyes, wash thoroughly with plenty of water and seek medical advice if symptoms persist.

If contact with skin occurs, it must be removed before curing takes place.

Wash off with an industrial skin clearer followed by plenty of soap and water. Do not use solvent.

Ensure adequate ventilation when using these products.